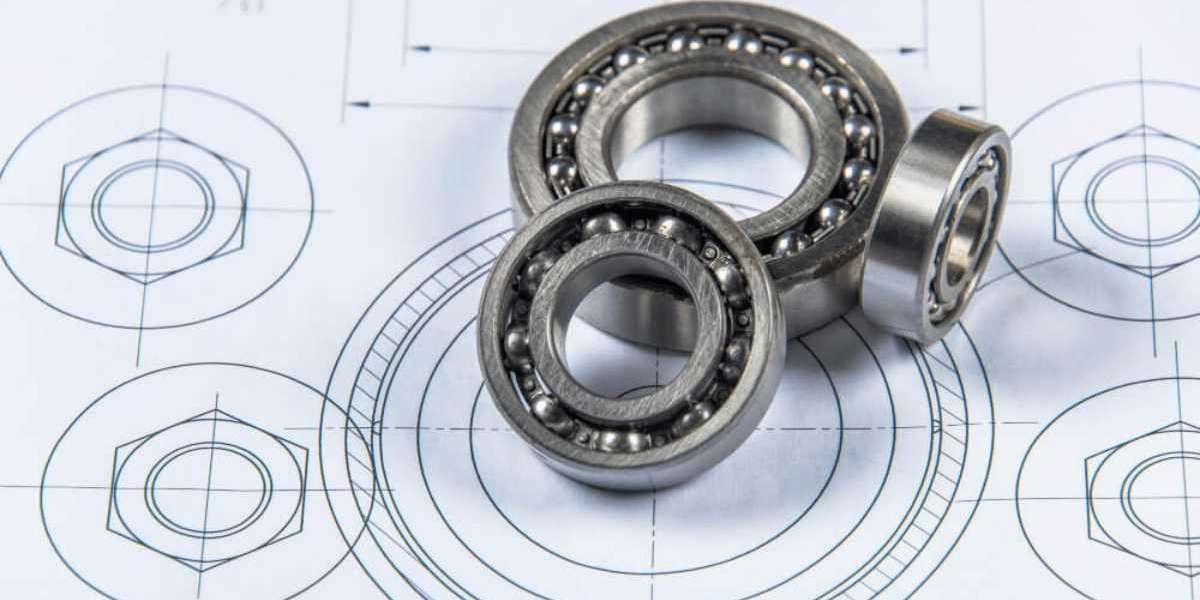

Nothing disrupts a factory floor faster than an unexpected bearing failure. Whether it's a robot arm slowing down, a conveyor line vibrating excessively, or a CNC machine losing precision, one small component can bring major operations to a halt. For manufacturers dealing with tight delivery schedules, every minute of downtime eats into productivity, profitability, and customer trust.

This is exactly why many industries are shifting toward premium-grade solutions like yuwei bearing—to eliminate preventable breakdowns that damage production efficiency.

The Hidden Cost of Using Low-Quality Bearings

Unplanned Downtime

Cheap bearings often seem cost-effective at first, but the real expense appears later when machines unexpectedly stop. Production teams face:

Missed deadlines

Emergency maintenance calls

Increased labor hours

Wasted materials due to inconsistent performance

A low-quality bearing becomes a silent profit drain.

Inconsistent Accuracy and Poor Load Handling

Modern machinery, especially robotic systems, demands consistency. When bearings wear out early or cannot handle radial and axial loads effectively, the entire system loses precision. This leads to:

Component misalignment

Reduced repeatability

Higher energy consumption

Increased risk of machine damage

For industries like automation, aerospace, packaging, and semiconductor manufacturing, precision isn’t optional—it’s mandatory.

Why High-Performance Bearings Matter More Than Ever

Improved Machine Life

High-precision bearings distribute load evenly, minimize friction, and handle continuous motion without early fatigue. This extends equipment lifespan and reduces long-term maintenance costs.

Better Speed and Stability

Reliable bearings reduce vibration, noise, and temperature fluctuations—ensuring smooth, stable operation during rapid production cycles.

Stronger Resistance Against Wear

Modern materials and heat-treatment processes significantly increase resistance to corrosion and deformation. This is crucial for demanding environments involving dust, chemicals, or heavy mechanical stress.

How Yuwei Bearing Solves These Production Challenges

Many manufacturers prefer yuwei bearing because of its focus on long-term reliability and advanced engineering. Built using strict quality standards, these bearings are designed to excel in harsh industrial applications such as:

Robotic automation

Precision machinery

Logistics equipment

CNC systems

High-speed production lines

Features that Set Yuwei Bearing Apart

Extreme Precision

Their bearings maintain tight tolerances that support consistent accuracy—ideal for robotics and CNC motion systems.

Enhanced Material Strength

Special alloy steel and precision grinding ensure durability, even under heavy or repetitive loads.

Stable Performance Under Continuous Operation

High-speed capability and advanced lubrication design reduce heat generation, extending bearing life significantly.

Zero-Compromise Quality Control

Each bearing passes multiple inspection stages, ensuring defect-free performance before reaching end-users.

Protect Your Production from Avoidable Disruptions

If your machines show symptoms like increased noise, abnormal vibration, overheating, or reduced accuracy, your bearings may already be declining. Replacing them with a higher-grade solution is not just a maintenance task—it's an investment in smoother operations.

Manufacturers today cannot afford downtime caused by unreliable components. Choosing bearings engineered for performance and longevity ensures continuous productivity, reduced maintenance costs, and greater confidence in your equipment.

Final Thoughts

Production stability depends heavily on the smallest components—especially bearings. By switching to high-reliability options like Yuwei Bearing, manufacturers protect themselves from costly failures, unexpected stoppages, and quality issues. When equipment runs smoothly, productivity rises, and the entire operation benefits.

If you want uninterrupted performance and long-term reliability, upgrading your bearing selection is the smartest step forward.