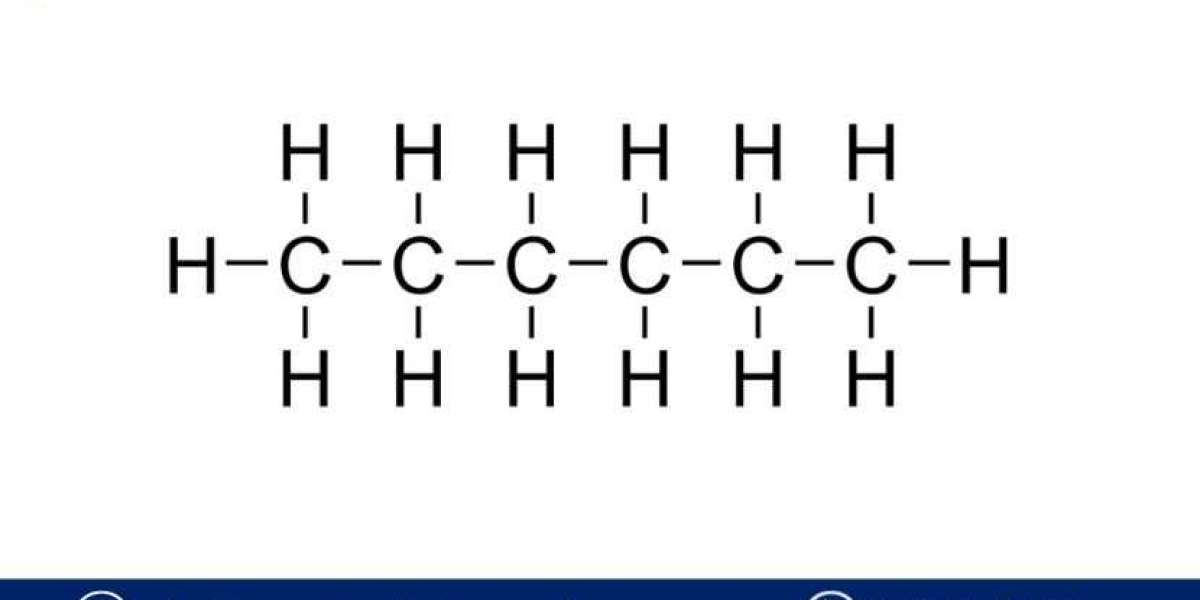

The Hexane Manufacturing Plant Project Report provides a comprehensive guide for entrepreneurs and businesses interested in establishing a hexane manufacturing facility. Hexane, an organic compound belonging to the alkane family, is a highly important solvent and is used in a wide variety of applications across industries such as chemical, pharmaceutical, agriculture, and food processing. This report delves into the necessary steps involved in setting up a hexane manufacturing plant, including the market demand, raw material sourcing, production processes, equipment requirements, and financial projections.

Hexane is commonly used as a solvent in industrial applications such as oil extraction, in the pharmaceutical industry for drug production, in agriculture for pesticide formulation, and in the food industry for refining edible oils. The global demand for hexane is growing, driven by the expansion of these sectors, making it a lucrative business opportunity for potential investors.

Market Overview and Demand Analysis

Global Demand for Hexane

The demand for hexane has been steadily increasing due to its widespread use in various industries. Hexane is primarily used as a solvent and is highly valued for its non-polar nature, which makes it effective in dissolving non-polar substances. Below are some key trends contributing to the rising demand for hexane:

Oil Extraction: One of the largest applications of hexane is in the extraction of vegetable oils from seeds and other plant material. This process is widely used in the food industry for refining edible oils. With the rising demand for edible oils globally, the need for hexane in oil extraction processes continues to grow.

Pharmaceutical and Chemical Industries: Hexane is used in the synthesis of various pharmaceutical products, and it is also employed in the production of chemicals like detergents, lubricants, and plastics. As the pharmaceutical and chemical industries expand, hexane consumption is expected to increase.

Agriculture and Pesticide Formulation: Hexane is used as a solvent in the formulation of pesticides and herbicides. The global agricultural sector, particularly in developing economies, is expanding, which will further drive the demand for hexane in pesticide manufacturing.

Food Industry: Hexane is widely used for oil extraction in the food industry, especially in the production of refined oils, such as soybean and sunflower oil. As global food consumption rises, the demand for hexane in the food industry is expected to increase.

Get a Free Sample Report with Table of Contents@

Raw Materials and Procurement Strategy

The primary raw material for hexane production is crude oil or natural gas, from which the hexane is derived. Below is a breakdown of the raw materials and procurement strategies for establishing a hexane manufacturing plant:

Key Raw Materials

Crude Oil: Hexane is produced through the refining of crude oil, so the availability of crude oil is crucial for the production process. Crude oil is separated into various hydrocarbons, and hexane is isolated as part of this process.

Natural Gas: Another source for hexane production is natural gas, particularly through the process of cracking, where heavier hydrocarbons are broken down to form lighter hydrocarbons, including hexane.

Catalysts and Additives: Depending on the specific production process, various catalysts may be required to enhance the cracking or refining processes to yield hexane.

Manufacturing Process

The manufacturing process for hexane involves the separation and refining of crude oil or natural gas. Below is a detailed breakdown of the steps involved in hexane production:

Step 1: Crude Oil Refining

- The first step in hexane production is the refining of crude oil. During this process, crude oil is heated and distilled into various components, including gasoline, diesel, and lighter hydrocarbons like hexane.

Step 2: Separation of Hexane

- In the distillation column, various hydrocarbons are separated based on their boiling points. Hexane is a light hydrocarbon, so it is separated from heavier hydrocarbons such as gasoline and kerosene. This separation is usually done in the naphtha range of the distillation process.

Step 3: Cracking (Optional)

- In some cases, hexane can also be produced through a process known as “cracking,” where larger hydrocarbons are broken down into smaller molecules. This process is often carried out in a refinery using high temperatures and catalysts.

Step 4: Purification

- Once hexane is isolated, it undergoes further purification to remove any impurities, such as sulfur or water, that may be present. This is usually done through additional distillation or filtration processes.

Step 5: Blending and Refining

- After purification, hexane is often blended with other hydrocarbons to meet specific industry standards and application requirements.

Step 6: Packaging

- The final hexane product is packaged in suitable containers, typically large drums or bulk storage tanks, and prepared for shipment to various industries.

Regulatory Compliance

Hexane manufacturing is subject to several regulations, especially regarding health and safety, environmental impact, and product quality. Here are some key regulatory considerations for the hexane manufacturing plant:

Environmental Regulations: Hexane manufacturing processes may release volatile organic compounds (VOCs) into the atmosphere. Regulatory bodies such as the Environmental Protection Agency (EPA) in the U.S. have strict guidelines on emissions, requiring manufacturers to implement emission control systems to limit pollutants.

Health and Safety Standards: Hexane is classified as a hazardous substance due to its flammability and potential health risks, including neurological damage from prolonged exposure. Occupational health and safety regulations, such as OSHA in the U.S., require manufacturers to implement safety measures, including proper ventilation, protective equipment, and exposure monitoring.

Quality Assurance: Hexane used in industrial applications must meet specific purity standards to ensure its effectiveness and safety. The manufacturing plant must implement quality control processes and ensure that the product meets industry standards such as ASTM or ISO certifications.

Transport and Storage Regulations: Hexane is highly flammable, so regulations regarding its safe transportation and storage must be followed. This includes using appropriate containers, labeling, and fire prevention measures.

Financial Projections and Cost Analysis

Setting up a hexane manufacturing plant requires a significant investment in infrastructure, machinery, and raw materials. Below is an outline of the expected costs and financial projections:

Capital Expenditure (CAPEX)

- Land and Building: The cost of land and construction for the manufacturing plant.

- Machinery and Equipment: Investment in distillation units, cracking units, storage tanks, filtration systems, and safety equipment.

- Raw Materials: Initial purchase of crude oil or natural gas for production.

- Licensing and Permits: Costs associated with acquiring the necessary licenses and permits for the manufacturing plant.

Operating Expenses (OPEX)

- Labor: Salaries for plant workers, including engineers, production staff, quality control personnel, and safety officers.

- Raw Material Costs: Ongoing procurement of crude oil or natural gas.

- Utilities: Costs for electricity, water, and other operational needs.

- Maintenance and Repairs: Regular maintenance and repair costs to ensure smooth plant operation.

Revenue Generation and Profitability

- Revenue Streams: The main revenue will come from the sale of hexane to industries such as pharmaceuticals, agriculture, oil extraction, and food processing.

- Profit Margins: Profitability will depend on factors such as production efficiency, raw material costs, and market pricing. Optimizing manufacturing processes to reduce waste and improve yields will contribute to higher profit margins.

Related Reports

https://www.expertmarketresearch.com/articles/top-doughnuts-manufacturers

Media Contact

Company Name: Claight Corporation

Contact Person: Peter Fernandas, Corporate Sales Specialist

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com