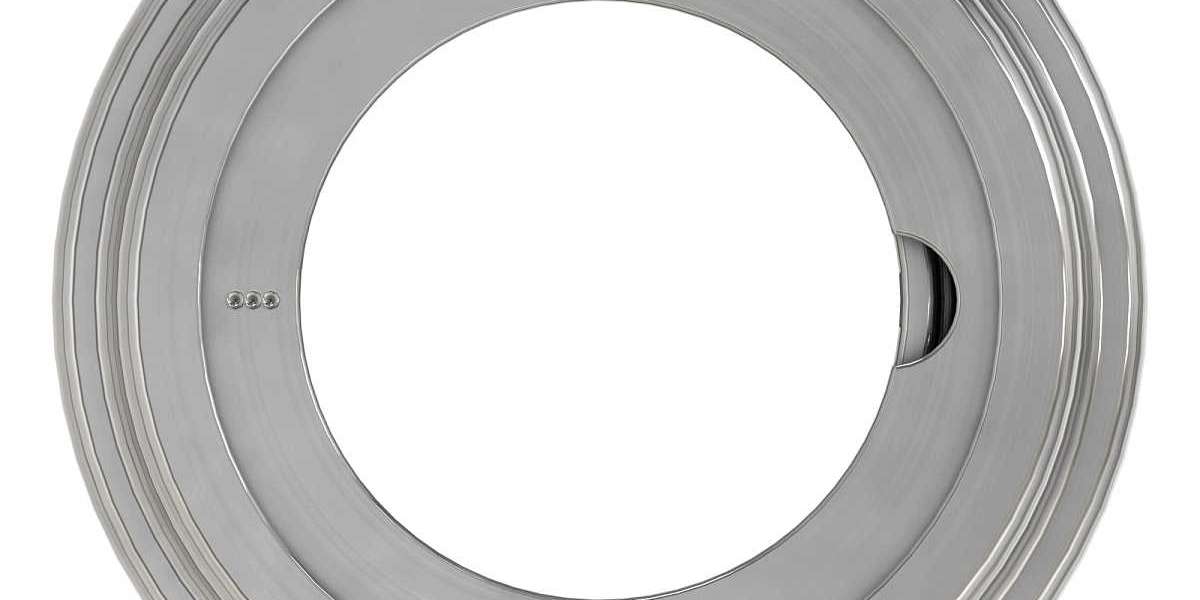

In the world of industrial machinery and automotive systems, even the smallest components can determine overall reliability. One such part is the AH229175 bearing. While it may seem minor, this bearing plays a vital role in reducing friction, supporting heavy loads, and ensuring smooth machine operation. Ignoring its maintenance or replacement can lead to downtime, costly repairs, and reduced equipment lifespan.

Why the AH229175 Bearing Matters

The AH229175 is a precision-engineered mechanical roller ball bearing built for demanding applications. It ensures proper load distribution and smooth rotation, which protects shafts, housings, and other connected components. Without it, machines are exposed to:

Excessive vibration and noise

Overheating from friction

Misalignment and instability

Early wear on adjoining parts

Replacing a failing AH229175 on time prevents small issues from becoming catastrophic failures.

Common Problems from Bearing Neglect

Machine Downtime – Production lines can stop suddenly due to a failed bearing.

Costly Repairs – Damaged shafts, motors, and gears multiply expenses.

Safety Concerns – Malfunctioning machinery increases the risk of accidents.

Lower Efficiency – Extra friction wastes energy and reduces productivity.

The True Cost of Ignoring AH229175

Many operators view bearings as small, replaceable parts and delay their maintenance. However, ignoring a single AH229175 can lead to expensive consequences, from motor replacements to full system shutdowns. Investing in a genuine AH229175 is far more affordable than facing unexpected breakdown costs.

Benefits of Using Genuine Bearings

Durability – Manufactured from high-grade materials for extended lifespan.

Consistent Performance – Provides stable, smooth, and reliable operation.

Energy Savings – Reduces resistance, lowering power consumption.

Preventive Protection – Shields connected components from excessive wear.

Warning Signs of Bearing Failure

Grinding or rattling noises from machinery

Sudden spikes in operating temperature

Visible cracks, wear, or discoloration

Unusual vibration during operation

Addressing these early warning signs prevents more severe damage.

Choosing the Right AH229175 Bearing

Not all bearings are equal. A genuine AH229175 ensures proper fit, high load capacity, and superior performance compared to cheaper alternatives. Always purchase from a trusted supplier to guarantee authenticity and reliability.

Conclusion

While often overlooked, the AH229175 bearing is critical for ensuring machine efficiency and preventing costly failures. Ignoring its maintenance can result in downtime, financial losses, and safety risks. Investing in genuine bearings ensures durability, efficiency, and long-term reliability. Protect your machines before it’s too late—replace and maintain your bearings proactively.