In the world of technology, few innovations have had as profound an impact as 3D printing. Also known as additive manufacturing, 3D printing has transformed industries ranging from healthcare to aerospace and even home design. This technology allows for the creation of objects from digital files by adding material layer by layer. What once seemed like a futuristic dream is now a part of our everyday lives, and its potential is only beginning to be realized.

What is 3D Printing?

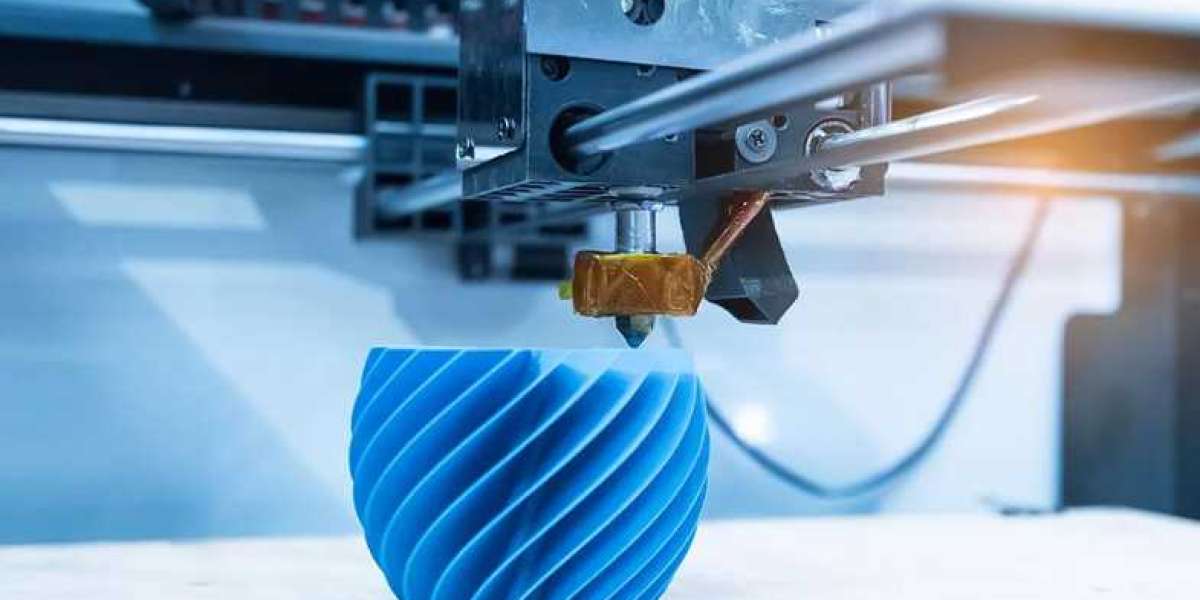

At its core, 3D printing is a process that converts digital designs into physical objects. The process starts with a 3D model, usually created using CAD (Computer-Aided Design) software or 3D scanning technology. The design is then broken down into thin layers, and the 3D printer creates each layer by adding material, whether it’s plastic, metal, resin, or even food. These layers build upon each other, eventually forming a complete object.

Unlike traditional manufacturing methods, which often involve subtracting material from a larger block (such as milling or carving), 3D printing adds material only where it’s needed. This makes it a more sustainable, efficient, and versatile method of production.

Types of 3D Printing Technologies

There are several different 3D printing technologies, each suited for different types of applications. Here are some of the most common ones:

Fused Deposition Modeling (FDM): This is the most widely used 3D printing technology, especially for consumer-level printers. FDM works by extruding a filament of thermoplastic material through a heated nozzle, layer by layer. This is ideal for creating prototypes, toys, and even functional parts.

Stereolithography (SLA): SLA uses a laser to cure liquid resin, layer by layer, to build the desired object. This method offers high precision and smooth surface finishes, making it ideal for jewelry, dental applications, and intricate designs.

Selective Laser Sintering (SLS): SLS uses a laser to sinter powdered materials, such as nylon or metal, into a solid structure. This method is commonly used for creating strong, functional parts in industries like aerospace, automotive, and healthcare.

Binder Jetting: In this process, a binder is selectively deposited onto a powder bed to create layers. Once the object is fully formed, it can be heated to sinter the material. This method is used for creating metal parts and prototypes.

Multi Jet Fusion (MJF): This technology uses a fine powder and applies binding agents with multiple jets, followed by a heating process. MJF is popular for creating complex, durable parts with excellent detail and surface finish.

The Applications of 3D Printing

3D printing has revolutionized many industries by enabling the rapid production of prototypes, end-use parts, and customized products. Let’s explore some of the most significant applications of this technology:

1. Healthcare and Medicine

One of the most exciting and life-changing applications of 3D printing is in the healthcare industry. 3D printing has enabled the creation of customized prosthetics, implants, and even human tissue. For example, 3D printers can produce custom prosthetic limbs that are tailored to an individual’s specific measurements, offering a more comfortable and functional fit.

In addition, surgeons can use 3D-printed models of a patient’s organs or bones to plan and practice complicated surgeries. This not only helps in improving the outcomes of surgeries but also reduces risks associated with them.

2. Aerospace and Automotive Industries

The aerospace and automotive sectors have also been quick to adopt 3D printing due to its ability to produce lightweight, complex, and durable parts. Engineers in these industries use 3D printing to create components that are lighter, more fuel-efficient, and cost-effective than traditional manufacturing methods.

For instance, NASA has been using 3D printing technology to manufacture parts for rockets and space stations, reducing the need for large inventories of parts. Similarly, car manufacturers like Ford and BMW have embraced 3D printing to prototype car parts quickly and even create custom-made components for high-performance vehicles.

3. Fashion and Jewelry

3D printing has given rise to a new era of creativity in the fashion and jewelry industries. Designers can create intricate, one-of-a-kind pieces of jewelry that would be difficult or impossible to make by hand. From personalized rings to avant-garde clothing, 3D printing allows for more freedom in design and faster production.

Additionally, 3D printing allows for the use of new materials that weren’t traditionally available, such as metals, resin, or even biodegradable plastics. The ability to create customized, tailored fashion pieces is a breakthrough for sustainable fashion as well.

4. Construction and Architecture

Another industry that is benefiting from 3D printing is construction. Large-scale 3D printers are being used to build homes and structures more quickly and at a lower cost than traditional construction methods. These 3D-printed buildings can also be customized to meet specific needs, such as creating homes with unique designs for different climates.

In addition to construction, architects can use 3D printing to create detailed scale models of buildings and urban planning projects. This helps in visualizing the end result and making design changes before committing to the full build.

5. Consumer Goods and Retail

3D printing has also made its way into the world of consumer goods. Many companies now offer 3D-printed items like shoes, phone cases, eyewear, and home décor. These products can be personalized to fit a customer’s preferences, such as adding their name or customizing the design.

Furthermore, the rise of on-demand 3D printing services means that consumers can order parts or products online and have them printed and delivered directly to their doorsteps, eliminating the need for mass production and reducing waste.

Advantages of 3D Printing

The benefits of 3D printing are numerous, particularly when compared to traditional manufacturing methods. Here are just a few of the advantages:

Customization: 3D printing allows for the production of unique, customized products that are tailored to individual needs, whether it’s a personalized prosthetic or a one-off piece of jewelry.

Speed: 3D printing can significantly speed up the production process. Prototypes can be created in hours, reducing the time it takes to bring new products to market.

Cost-Effectiveness: Because 3D printing doesn’t require expensive molds or tools, it can be a more affordable option for small production runs and prototyping.

Complexity: 3D printing can create objects with intricate, complex geometries that are impossible or too costly to make using traditional manufacturing methods.

Reduced Waste: Since 3D printing only uses the exact amount of material needed, there is less waste produced compared to subtractive manufacturing methods.

The Future of 3D Printing

As 3D printing continues to evolve, its potential is seemingly limitless. In the future, we may see even more revolutionary advancements, such as 3D-printed food, the ability to print entire buildings, and the development of new materials for 3D printing that are more sustainable and versatile.

Moreover, as more industries embrace 3D printing, the technology will likely become more accessible and affordable, allowing individuals and small businesses to take advantage of its benefits. This democratization of technology will open up new opportunities for innovation and creativity across various sectors.

Conclusion

3D printing has already made a significant impact on industries around the world, and its potential for transformation is only beginning. From healthcare to manufacturing, this technology is enabling new levels of efficiency, customization, and sustainability. As it continues to evolve, 3D printing will undoubtedly play an even larger role in shaping the future of innovation and production across the globe. Whether it's creating life-saving medical devices or reducing waste in manufacturing, the possibilities of 3D printing are boundless, and the world is just getting started.