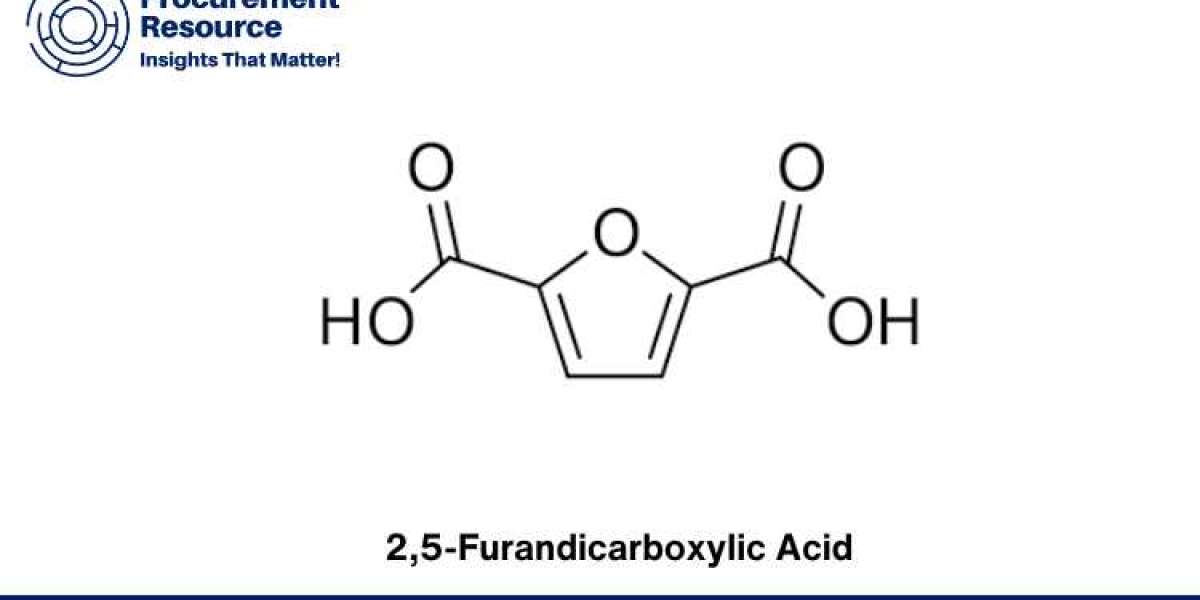

2,5-Furandicarboxylic acid (FDCA) is one of the key organic compounds of interest in various industries, especially for its potential applications in bioplastics, coatings, and pharmaceuticals. With the rising demand for sustainable and environmentally friendly alternatives to petroleum-based products, FDCA is becoming a focal point in the transition to a bio-based economy. This article delves into the detailed production cost report for 2,5-Furandicarboxylic acid, covering essential aspects such as cost models, pre-feasibility studies, industrial trends, labor charges, utilities, logistics, and the supply chain. This will offer insights to businesses and stakeholders about the economic viability of FDCA production and its prospects in the market.

Extensive 2,5-Furandicarboxylic Acid Production Cost Report: Key Elements

The production cost of 2,5-Furandicarboxylic acid is determined by several interconnected factors. Understanding these factors can help businesses in managing their expenses, ensuring efficient production, and maintaining profitability. Below is an in-depth look into the key elements of the FDCA production cost report.

Cost Model for 2,5-Furandicarboxylic Acid Production

The cost model for FDCA production revolves around several variables, such as raw materials, processing costs, labor, energy consumption, and logistical expenses. In a typical FDCA production process, raw materials like glucose, fructose, and other renewable biomass sources are utilized. The synthesis of FDCA involves processes like catalytic oxidation or dehydration, which require advanced technologies.

Raw materials often make up a significant portion of the production cost. The fluctuations in the prices of biomass and sugars can have a direct impact on the overall production cost of FDCA. Additionally, the manufacturing process requires significant energy input, which influences the cost structure.

Request For Sample: https://www.procurementresource.com/production-cost-report-store/2-5-furandicarboxylic-acid/request-sample

Labor charges also play an essential role in determining the overall production cost. Skilled labor for plant operation, maintenance, and quality assurance adds up to the total cost. Furthermore, the operational efficiency and throughput of the production facility have a direct correlation with labor costs.

The cost model also accounts for the implementation of sustainable and energy-efficient production technologies, which can drive the overall cost up but offer long-term benefits in terms of operational savings and environmental impact reduction.

Pre-feasibility of FDCA Production

Before setting up an FDCA production facility, a pre-feasibility study is essential. This study assesses the technical and financial feasibility of launching the production plant. The main elements evaluated in a pre-feasibility study for FDCA production include:

Market Demand and Trends: The growth in demand for bio-based materials, such as FDCA-based polymers (e.g., PEF – Polyethylene Furanoate), is expected to drive the industry forward. Evaluating demand trends helps in estimating production volumes and potential profitability.

Technology Assessment: Different production routes for FDCA, such as catalytic oxidation and biotechnological pathways, require different levels of investment and technological infrastructure. The most cost-effective and scalable technology must be selected to minimize production costs.

Investment in Facilities and Infrastructure: Establishing the necessary infrastructure such as reactors, fermentation tanks, and distillation units requires significant capital investment. The pre-feasibility study evaluates the potential return on investment (ROI) based on projected costs and profits.

Industrial Trends Impacting FDCA Production Costs

The industrial trends in the production of FDCA are primarily driven by technological advancements and sustainability goals. Innovations in biocatalysis, better sugar conversion technologies, and the increasing availability of renewable feedstocks are continuously lowering production costs.

Additionally, there is growing pressure on industries to adopt green chemistry and reduce their carbon footprint, leading to investments in renewable feedstocks and eco-friendly technologies. As a result, FDCA production is gradually becoming more competitive compared to conventional petrochemical processes. Moreover, the global shift toward sustainable packaging solutions, particularly in the food and beverage industry, is driving the demand for FDCA-based polymers, further incentivizing cost optimization in its production.

Labor Charges in 2,5-Furandicarboxylic Acid Production

Labor charges are a critical factor in determining the overall cost of FDCA production. The highly specialized nature of the technology and the need for skilled professionals to operate, monitor, and maintain the production processes lead to relatively higher labor costs. Plant operators, engineers, process developers, and quality control personnel are integral to the efficient functioning of the production facility.

Moreover, labor charges in different regions vary based on local wage standards, which can further influence the cost structure. For instance, manufacturing in regions with lower labor costs, such as Southeast Asia, may present more affordable operational expenses compared to high-wage economies.

Utilities: Power and Water Usage

The production of 2,5-Furandicarboxylic acid involves significant energy consumption, particularly in the chemical transformation processes. Energy, both electrical and thermal, forms a substantial portion of the total production cost. Optimizing energy usage through energy-efficient processes, recycling heat, or utilizing renewable energy sources can reduce costs in the long run.

Water usage is another critical factor in FDCA production, particularly during purification and cooling stages. As sustainability practices evolve, production plants may seek water-recycling systems to lower costs while adhering to environmental regulations.

Logistics and Supply Chain Management

Logistics and supply chain management play an essential role in controlling production costs. The transportation of raw materials to the production facility, along with the distribution of the final product, incurs costs that must be taken into account in the overall cost model.

Supply chain efficiency can significantly affect the cost structure. For instance, sourcing renewable feedstocks locally can help reduce transportation costs, while establishing efficient distribution networks can lower distribution costs. Additionally, supply chain management strategies that optimize inventory and minimize waste can have a favorable impact on production costs.

Request a Free Sample

For more in-depth analysis and data on 2,5-Furandicarboxylic acid production costs, procurement strategies, and detailed cost models, you can request a free sample report. This comprehensive report will give you access to the latest cost data, technological advancements, and market insights.

Request a Free Sample: https://www.procurementresource.com/production-cost-report-store/2-5-furandicarboxylic-acid/request-sample

Procurement Resource and Cost Optimization

Procurement Resource offers invaluable insights into the production costs of a wide range of chemicals, including FDCA. Their in-depth reports, cost models, and market analysis help businesses optimize their production costs by evaluating the feasibility of investment, assessing risk, and forecasting future trends. With data-driven insights, companies can make informed decisions to enhance profitability and maintain competitive advantages in the FDCA market.

By leveraging the tools and resources provided by Procurement Resource, businesses can effectively navigate the complexities of the 2,5-Furandicarboxylic acid production process, optimize their cost structure, and stay ahead of emerging industrial trends.

The production cost of 2,5-Furandicarboxylic acid is influenced by several dynamic factors, including raw material prices, technology, labor charges, utilities, logistics, and supply chain efficiency. The growing interest in bio-based chemicals and sustainable materials is driving innovation in FDCA production, which has the potential to reduce costs and improve profitability in the coming years. Understanding these factors, along with detailed cost models and pre-feasibility assessments, is crucial for stakeholders to make informed decisions and remain competitive in this rapidly evolving market.

For those looking to explore detailed insights into the production cost, technologies, and market trends, requesting a sample report or consulting with procurement experts can be a valuable next step.

Contact Us:

Company Name: Procurement Resource

Contact Person: Endru Smith

Email: sales@procurementresource.com

Toll-Free Number: USA Canada - Phone no: +1 307 363 1045 | UK - Phone no: +44 7537171117 | Asia-Pacific (APAC) - Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA