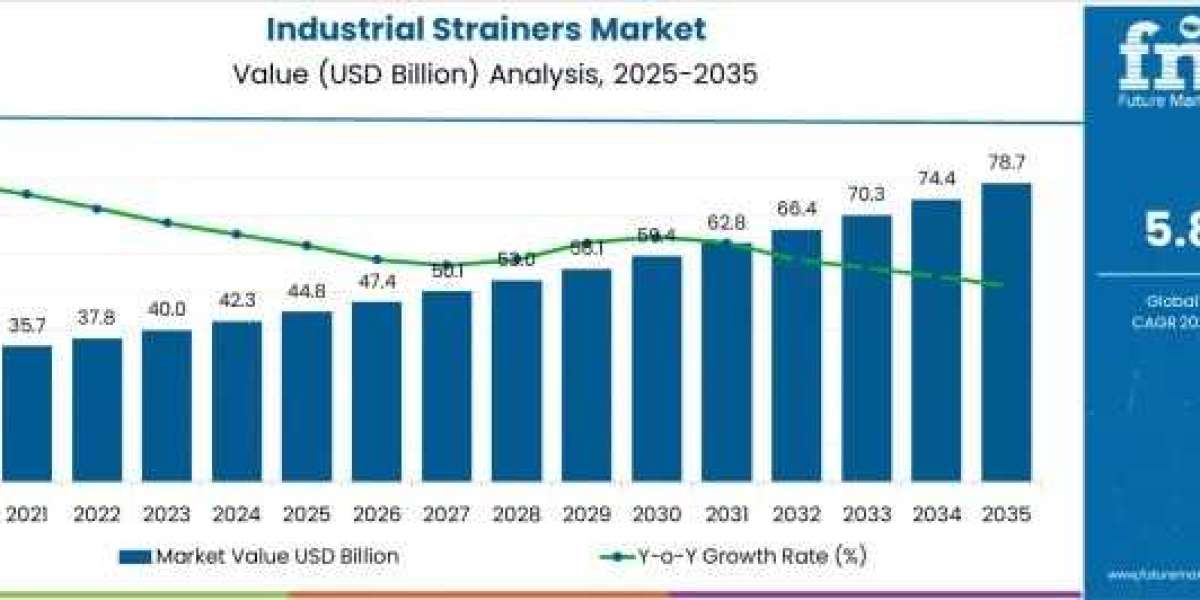

The Industrial Strainers Market is projected to grow from USD 44.8 billion in 2025 to USD 78.7 billion by 2035, registering a CAGR of 5.8%. Increasing demand from chemicals, petrochemicals, water treatment, and power generation is driving adoption. Strainers are critical for pipeline protection, ensuring uninterrupted operations and minimizing downtime. Their role in enhancing operational efficiency has made them indispensable in process industries worldwide.

Key Drivers:

- Rising need for filtration in process-heavy industries

- Regulatory emphasis on wastewater and environmental compliance

- Technological advancements in durability and material quality

Request For Sample Report | Customize Report | Purchase Full Report–

https://www.futuremarketinsights.com/reports/sample/rep-gb-14147

Segment Analysis: Y-Type Strainers Lead

The Y-type segment is expected to dominate with 48.6% of market revenue in 2025. Its compact design, cost efficiency, and suitability for high-pressure pipelines drive adoption across industries. Easy installation and low maintenance requirements make Y-type strainers a versatile choice in both horizontal and vertical pipelines.

Highlights:

- Continuous flow with effective particle filtration

- Cost-effective and reliable for diverse applications

- Popular in water treatment, chemical, and general manufacturing sectors

Material Insights: Iron Strainers Remain Dominant

Iron strainers capture 44.2% of the market share in 2025, favored for strength, durability, and affordability. They perform well under high mechanical stress and varying pressure conditions, making them ideal for heavy-duty applications.

Benefits:

- Long-lasting in industrial environments

- Suitable for oil gas, water treatment, and manufacturing

- Cost-efficient compared to steel or bronze alternatives

Regional Market Outlook

North America, Europe, and Asia-Pacific are driving global growth.

- Europe: Innovations in self-cleaning, electric motor-driven, and revolving screen strainers improve operational efficiency. Polymer-based strainers are gaining traction.

- Asia-Pacific: Rapid industrialization in India, China, and ASEAN countries fuels demand, particularly in chemicals, food beverage, and general manufacturing. Low-cost Chinese strainers are expanding market reach.

Applications Across Industries

Strainers are essential in cooling towers, pipelines, and process systems. Multi-element and self-cleaning variants reduce manual maintenance while improving efficiency.

Key Applications:

- Basket strainers in wastewater and food beverage sectors

- Industrial oil strainers in automotive and petroleum industries

- Duplex and simplex strainers in chemical processing and energy

Leading Manufacturers

Key market players are: Eaton Plc, Industriefabrik Schneider GmbH, Russell Finex Ltd, European Filter Solutions Ltd, Techmatic, Inc., Tate Andale LLC, George Fischer Pte. Ltd, Asahi America, Marck Care (MNC) Strainers, Hayward Industries, Inc., and Spears Manufacturing.

Focus Areas:

- Customer retention and service innovation

- Product differentiation by application and material

- Expansion into cyclical industries like oil, gas, and mining

Market Outlook and Strategic Insights

Industrial strainers are no longer just protective devices; they are vital efficiency enablers supporting sustainability, uptime, and reduced operational costs. End users are increasingly investing in advanced straining solutions that optimize maintenance cycles and ensure process continuity.