Introduction

In modern cities, underground cables play a crucial role in transmitting electricity and communication signals. Unlike overhead cables, these underground cables are safe from weather damage but are difficult to inspect when faults occur. Underground Cable Fault Detection is essential to identify and fix issues in cables without unnecessary digging. This article explores the importance, methods, and techniques used for fault detection in underground cables.

Why is Underground Cable Fault Detection Important?

Underground cables provide a reliable power and communication network, but faults can cause major disruptions. Some key reasons why Underground Cable Fault Detection is important include:

Avoiding power outages: Faulty cables can cause blackouts affecting homes, businesses, and industries.

Reducing repair time: Quick detection helps in fast repairs, minimizing inconvenience.

Cost efficiency: Detecting faults early prevents extensive damage and reduces repair costs.

Ensuring safety: Faulty cables can cause electrical hazards, making detection crucial for public safety.

Common Causes of Underground Cable Faults

Several factors can lead to underground cable faults. These include:

Physical Damage: Excavation, construction work, or road repairs can damage cables.

Moisture and Water Seepage: Water entering cable insulation can cause short circuits.

Aging and Wear: Over time, cables degrade due to material fatigue.

Electrical Overload: Excessive current flow can heat cables, leading to faults.

Rodents and Insects: Some underground animals chew on cable insulation, causing damage.

Methods of Underground Cable Fault Detection

To accurately locate faults in underground cables, various methods are used. Below are some commonly applied techniques:

1. Time-Domain Reflectometry (TDR)

TDR works by sending electrical pulses through the cable. When the pulse hits a fault, a reflection occurs, which is measured to determine the fault's location.

Advantages:

Quick and accurate results

Works well for short-distance cables

Disadvantages:

Less effective for long cables

Expensive equipment required

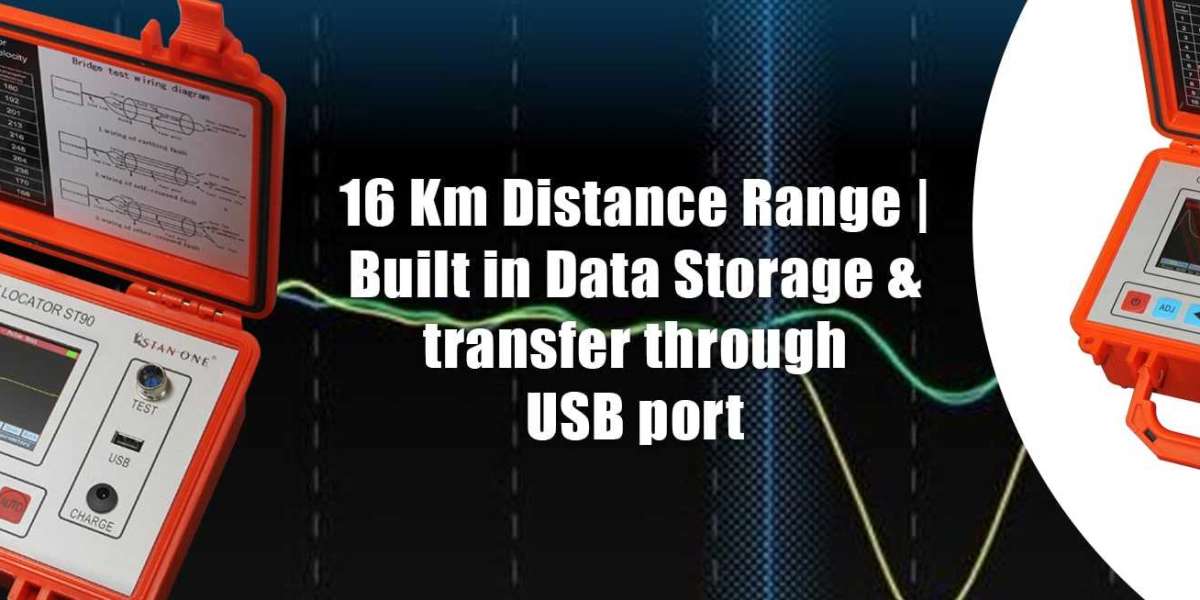

2. Murray Loop Test

This method uses a bridge circuit to locate faults. It is commonly used for Underground Cable Fault Detection in low-resistance circuits.

Advantages:

Simple and cost-effective

Suitable for short circuits

Disadvantages:

Less effective for high-resistance faults

Requires access to both ends of the cable

3. Earth Resistance Test

This technique measures the resistance of the earth around the cable to detect faults.

Advantages:

Easy to perform

Useful for detecting insulation failures

Disadvantages:

Less accurate compared to advanced methods

Cannot locate faults precisely

4. Cable Thumper Test

This method involves sending high-voltage pulses through the cable to create an audible noise at the fault location.

Advantages:

Effective for pinpointing exact fault locations

Works well for buried cables

Disadvantages:

Can cause additional damage if not used carefully

Requires trained professionals

5. Acoustic Fault Detection

This technique uses sound waves to detect faults by analyzing the noise emitted from faulty cables.

Advantages:

Non-destructive method

Can be used on live cables

Disadvantages:

Requires specialized equipment

Works best in quiet environments

Modern Techniques in Underground Cable Fault Detection

With advancements in technology, newer methods are emerging for more accurate and efficient Underground Cable Fault Detection. Some of these include:

AI-Based Fault Detection: Artificial intelligence is used to analyze electrical signals and predict faults before they occur.

Thermal Imaging: Infrared cameras detect heat patterns in cables to locate faults.

Smart Sensors: Embedded sensors in cables monitor voltage, temperature, and insulation status for real-time fault detection.

Conclusion

Underground Cable Fault Detection is essential for maintaining a reliable electrical and communication network. Various methods, from traditional bridge tests to advanced AI-based techniques, help locate faults efficiently. Implementing the right detection technique saves time, reduces costs, and ensures safety. As technology continues to improve, detecting underground cable faults will become even faster and more accurate, benefiting industries and consumers alike.