1. Evaluate the Company’s Experience and Expertise

Experience plays a major role in achieving high production standards. A company with several years of expertise in injection moulding will understand different material properties, mould complexities, and production challenges. They are more likely to offer:

Accurate mould design

Efficient production cycles

Fewer errors and material wastage

Established brands such as Tesseract 3D combine industry knowledge with advanced technology to deliver high-precision moulded parts across various sectors.

2. Check the Quality of Materials Used

Material quality directly affects the durability, strength, and performance of your final product. A reliable injection moulding service should offer a wide range of certified materials such as:

ABS

Nylon

Polypropylene

Polycarbonate

Engineering plastics

Top-tier service providers ensure that the materials are sourced from trusted suppliers and meet required industry standards.

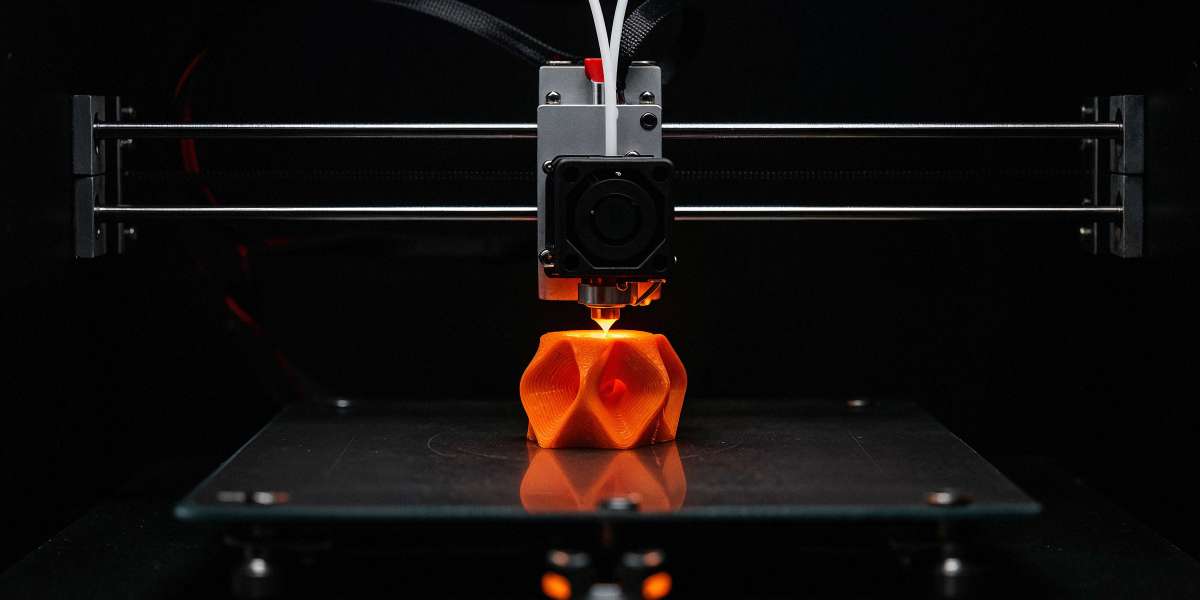

3. Evaluate Manufacturing Capabilities and Technology

Modern injection moulding relies heavily on advanced manufacturing tools and automation. Before choosing a service, assess whether the company uses:

High-precision CNC machines

Automated injection moulding systems

In-house mould design and prototyping

Quality control testing equipment

Companies like Tesseract 3D invest in modern machinery to maintain tight tolerances and consistent part quality, making them a reliable partner for both small and large-volume production.

4. Review the Company’s Quality Assurance Processes

A dependable injection moulding service must follow strict quality assurance practices. Look for certifications such as ISO and inquire about their inspection methods. These may include:

First article inspection

Dimensional accuracy checks

Material verification

Final product testing

Quality-driven brands ensure every stage is monitored to deliver defect-free results.

5. Consider Lead Times and Delivery Efficiency

Fast and reliable delivery is essential, especially for businesses operating on strict schedules. Before finalizing a partner, ask about:

Typical production lead times

Response speed for mould revisions

Shipping and logistics capabilities

A reliable company should be transparent about timelines and committed to meeting your deadlines.

6. Evaluate Pricing Transparency

While cost is important, it should never compromise quality. Choose a provider that offers clear and competitive pricing. The service should include mould design, prototyping, production, post-processing, and any additional customization.

Brands like Tesseract 3D focus on providing value-driven pricing without hidden charges while ensuring premium-quality output.

Conclusion

Selecting the right injection moulding service is essential for achieving high-quality, durable, and precise products. From evaluating experience and technology to assessing material quality and pricing, each factor plays a vital role in choosing the best fit for your manufacturing needs. With modern tools, expert engineers, and a commitment to quality, Tesseract 3D continues to be a trusted partner for businesses seeking reliable injection moulding solutions.