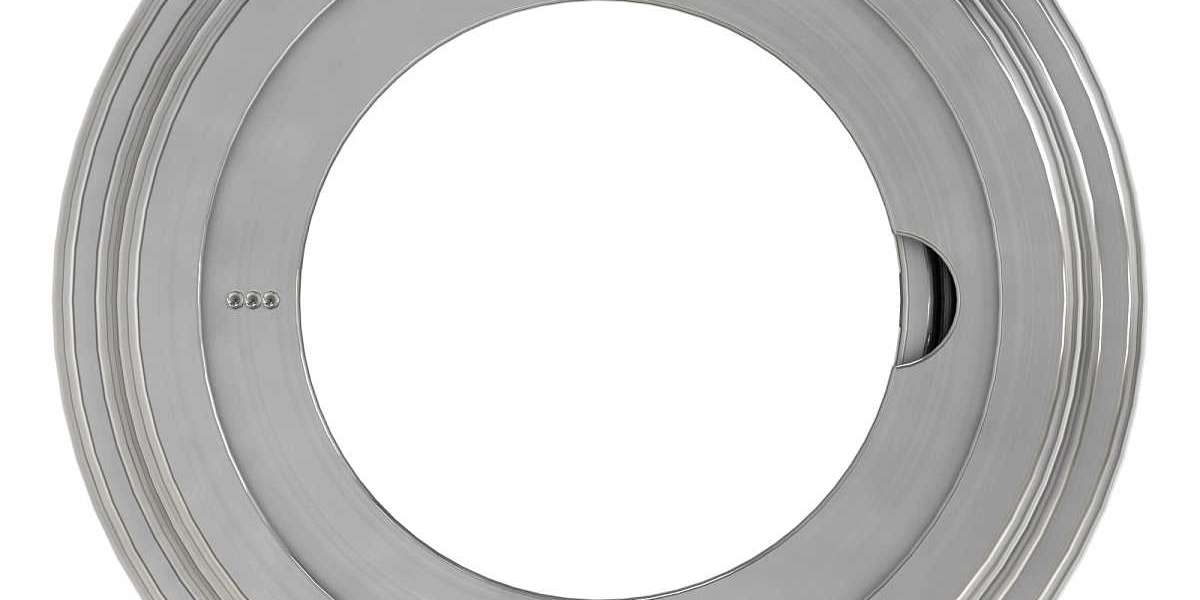

Industries lose countless hours and revenue due to sudden equipment failures. One of the biggest hidden causes? Worn-out or low-quality bearings that cannot handle high-load, continuous-operation environments. If you’ve faced repeated machine stoppages, overheating shafts, or inconsistent rotational performance, the ah229175 bearing may be exactly what your machinery needs to restore reliability and eliminate unnecessary downtime.

Why the ah229175 Matters for Heavy-Duty Machinery

Industrial machines operate under constant load, vibration, and high temperature. This creates intense pressure on bearings, especially when they function as the core stabilizing element of rotating assemblies. The ah229175 bearing is engineered to withstand these harsh conditions, offering long service life and stable performance.

Its design supports high radial and axial loads while maintaining smooth motion, reducing friction, and preventing shaft misalignment—three key factors that directly impact operational uptime.

To explore the technical specifications, you can visit the product page here:

ah229175

Common Pain Points Solved by the ah229175

1. Repeated Equipment Shutdowns

Poor-quality bearings often fail under continuous load, causing machinery to overheat or seize. The robust construction of the ah229175 reduces failure frequency and ensures stable rotation even in demanding environments.

2. High Maintenance Costs

Frequent bearing replacements drive up operational expenses. The extended lifespan and wear-resistant materials of this bearing significantly lower your long-term maintenance budget.

3. Vibration and Noise Issues

Imbalanced or low-precision bearings cause irregular movement that generates noise and vibration. This bearing’s accurate fit minimizes these disturbances and protects connected components from damage.

4. Production Losses

Downtime is expensive. By using an industrial-grade solution like the ah229175, factories maintain continuous workflow and reduce unexpected interruptions.

Key Features That Enhance Performance

High Load Capacity

The bearing is engineered with durable components capable of managing intense operational stress without deforming or losing efficiency.

Precision-Machined Components

This ensures smoother rotation, less friction, and high-speed performance without compromising stability.

Corrosion and Heat Resistance

The materials used in the ah229175 help it withstand high temperatures, contamination, and moisture—conditions common in manufacturing plants, construction equipment, and industrial machinery.

Extended Service Life

Its rugged internal design and optimized lubrication channels help minimize internal wear, allowing the bearing to remain reliable for long periods.

Learn more here:

ah229175

Where the ah229175 Performs Best

This industrial bearing is a preferred choice for:

Heavy machinery

High-speed mechanical systems

Conveyor systems

Agricultural machinery

Manufacturing and processing equipment

Construction equipment

Its compatibility with multiple systems makes it a versatile solution for operators who need a single, reliable bearing across different machines.

Why Investing in Quality Bearings Saves Money Long-Term

Choosing a high-performance bearing like the ah229175 ensures fewer breakdowns, lower repair costs, longer machine life, and better operator safety. Cutting costs with low-quality components usually results in higher expenses due to failures, so investing in reliable parts is always the smarter long-term approach.

Final Thoughts

If your machinery is suffering from inconsistent rotation, rising maintenance costs, or frequent breakdowns, upgrading to a dependable industrial solution like the ah229175 bearing can transform your machine’s performance. Its strength, reliability, and long service life make it a smart investment for factories and equipment owners focused on efficiency and productivity.