The transformation from mechanical switches and analog gauges to digital touchscreen interfaces represents one of the most significant evolutions in aviation history. Rugged display technology has fundamentally changed how pilots interact with aircraft systems, how maintenance crews diagnose issues, and how mission planners optimize operational effectiveness. For procurement managers and design engineers at major aerospace companies, understanding this revolution is essential for next-generation platform development.

The Evolution from Physical Controls to Digital Interfaces

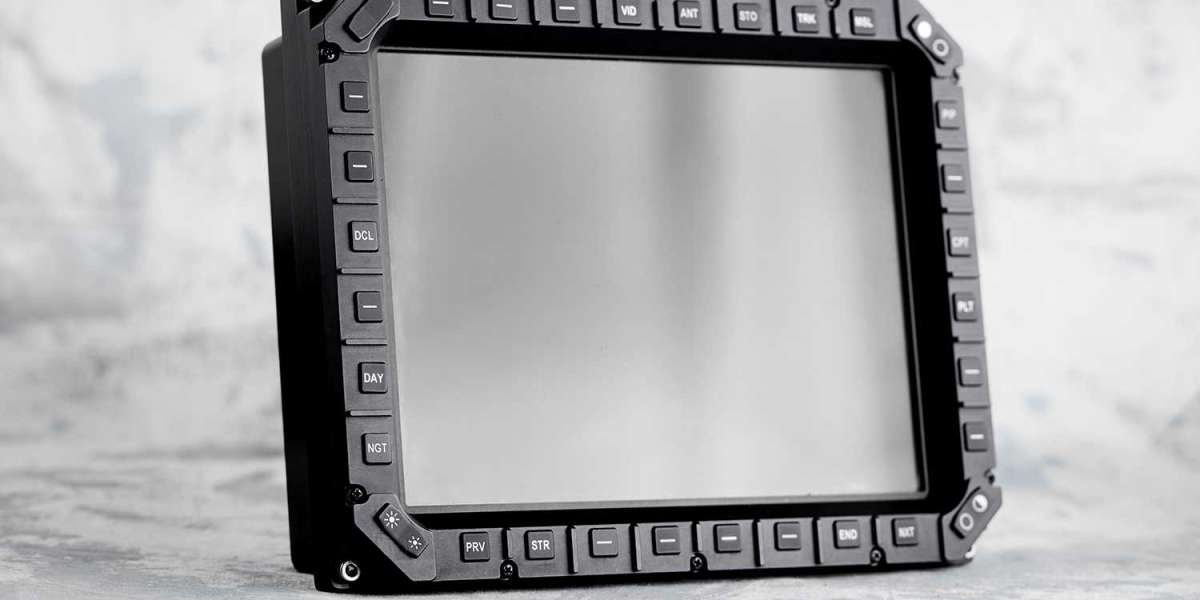

Traditional cockpits featured hundreds of discrete switches, knobs, and mechanical gauges—each representing a potential failure point and adding considerable weight to aircraft. The introduction of multifunction displays (MFDs) began consolidating these controls, but early systems lacked the intuitive interaction that touchscreen technology now provides. Modern aircraft control panels leverage advanced touch technology to reduce cockpit complexity while simultaneously expanding functional capabilities.

This transition addresses a critical challenge in military aviation: the need to integrate increasingly sophisticated mission systems without overwhelming pilots with physical controls. Touchscreen interfaces allow dynamic reconfiguration based on mission phase, presenting only relevant controls and reducing cognitive workload during high-stress operations.

Enhanced Situational Awareness Through Integrated Data Visualization

Contemporary rugged display systems serve as central information hubs, synthesizing data from dozens of aircraft subsystems, sensors, and external sources into coherent visual presentations. High-resolution screens now display tactical overlays, weather radar, terrain mapping, threat tracking, and system diagnostics simultaneously on customizable layouts. Pilots can manipulate this information through intuitive touch gestures—pinch-to-zoom on tactical maps, swipe to change display pages, or tap to drill down into system parameters.

The integration of synthetic vision technology with touchscreen controls enables pilots to maintain spatial orientation in degraded visual environments, significantly enhancing safety margins during challenging operations. Touch interfaces allow rapid reconfiguration of these displays to emphasize different data sets as operational priorities shift.

Ruggedization Requirements for Mission-Critical Environments

Rugged display manufacturers face unique challenges when adapting consumer-grade touchscreen technology for aerospace applications. Military and commercial aviation platforms operate across temperature extremes, sustained vibration, electromagnetic interference, and altitude ranges that would destroy standard displays within hours. Advanced engineering solutions address these challenges through specialized component selection, thermal management systems, and robust mechanical designs.

Modern military-grade displays must maintain touch sensitivity while pilots wear heavy flight gloves or protective equipment. This requires projected capacitive touch controllers calibrated for reduced conductivity conditions, along with display coatings that prevent false inputs from water, dirt, or debris accumulation. Leading rugged display manufacturers like Aeromaoz have developed proprietary technologies that ensure consistent touch performance across these challenging operational scenarios in aviation, UAV, and naval platforms worldwide.

Weight Reduction and Space Optimization

One often-overlooked benefit of touchscreen aircraft control panels is the dramatic reduction in cockpit weight and volume. Eliminating hundreds of mechanical switches, their associated wiring harnesses, and mounting structures can save 50-150 kilograms in military aircraft—weight that translates directly to increased payload capacity, extended range, or improved maneuverability. Helicopters and armored vehicles particularly benefit from this weight reduction, as every kilogram saved improves power-to-weight ratios and operational efficiency.

The compact form factor of touchscreen displays also creates opportunities for cockpit redesign, improving pilot visibility and ergonomics. System integrators can position displays for optimal viewing angles while consolidating controls into smaller spaces, leaving room for additional equipment or improved crew comfort.

Maintenance and Lifecycle Cost Benefits

Touchscreen interfaces dramatically simplify aircraft maintenance compared to mechanical control systems. Diagnostic routines accessed through intuitive touch menus allow technicians to identify faults rapidly without specialized test equipment. Built-in test functionality can exercise aircraft systems through touch commands, reducing troubleshooting time from hours to minutes.

The modular nature of modern rugged displays enables quick replacement of failed units, with configuration data automatically loaded from central maintenance computers. This approach reduces mean time to repair (MTTR) and minimizes spare parts inventory requirements—critical considerations for operators managing global fleets with dispersed maintenance facilities.

Software-Defined Functionality and Future-Proofing

Perhaps the most revolutionary aspect of touchscreen aircraft control panels is their software-defined nature. Unlike mechanical switches locked into specific functions, touchscreen interfaces can be updated through software modifications to support new capabilities, mission profiles, or user preferences. This flexibility allows platforms to adapt to evolving threats and operational requirements throughout multi-decade service lives without expensive hardware retrofits.

Operators can customize interface layouts for different mission types, pilot experience levels, or theater-specific requirements through simple software configuration changes. This adaptability extends platform relevance and protects procurement investments against technological obsolescence.

Conclusion

The revolution in rugged display technology continues accelerating as manufacturers push boundaries in durability, functionality, and integration. For system engineers and procurement professionals developing next-generation platforms, selecting proven touchscreen solutions from experienced rugged display manufacturers ensures mission success while reducing lifecycle costs and maximizing operational flexibility across diverse deployment scenarios.