In apparel decoration, machine embroidery provides a durable and high-quality finish. While stock designs are common, custom embroidery digitizing is the service that converts a specific piece of artwork, such as a company logo or unique illustration, into a stitch-ready file. This process is far more than a technical conversion; it is a meticulous craft that ensures a client's vision is accurately translated into thread.

What Defines Custom Digitizing?

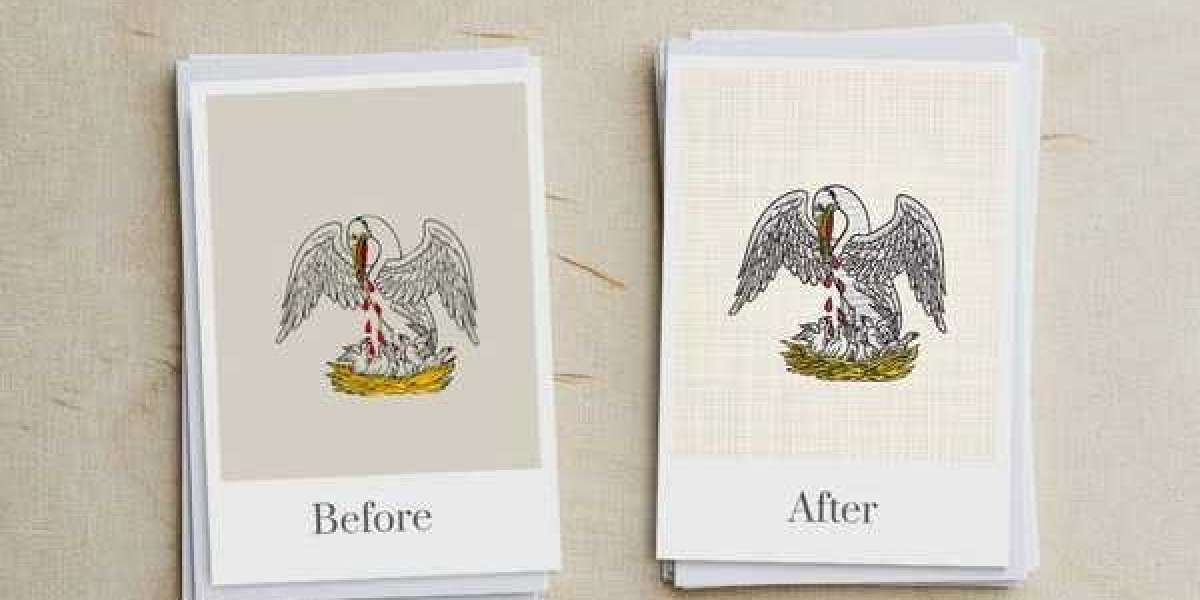

Unlike using pre-made designs or automated software, custom digitizing starts with an analysis of your unique image. A professional digitizer functions as both an artist and a technician, studying the artwork's complexity, color palette, and fine details. From there, they manually plot a path for every stitch, making critical decisions that directly impact the final product's quality.

This tailored approach accounts for the most important variable, the final application. A design for a structured baseball cap requires a different file structure, stitch density, and underlay than the same design on a soft, stretchy t-shirt. Custom digitizing builds the file for a specific purpose from the ground up, which is essential for a superior and consistent result.

Translating a Design into a Physical Product

A digitizer's expertise is demonstrated in how they solve the inherent challenges of turning a flat image into a textured, stitched design. Their work ensures the final product is clean, durable, and professional.

One of the first tasks is interpreting the artwork to maintain its integrity. A skilled digitizer knows that thread cannot replicate digital gradients or extremely fine lines. They will adapt these elements into solid fill stitches and clean satin stitch borders that will embroider cleanly.

This same expertise applies to small lettering, a common failure point in low-quality files. A professional uses specific underlay techniques and adjusts stitch parameters to ensure even the smallest text remains crisp and legible.

The digitizer must also account for the physics of the fabric. Materials like fleece and towels have a high pile, so stitches can sink and disappear. To prevent this, the digitizer programs a dense foundation of underlay stitches and may increase the design's overall density.

Conversely, on a thin polo shirt, they will reduce density and use a lighter underlay to prevent the fabric from puckering under the thread's tension. This planning prevents the most common forms of embroidery failure.

Finally, the process is optimized for production efficiency. For multi-color designs, a digitizer plans the pathing, the sequence in which the machine sews to minimize jumps and trims. This creates a cleaner back and a faster, more efficient sewing process, which is especially important for larger orders.

A Collaborative Approach to Quality

Ultimately, custom embroidery digitizing is a collaborative service. An experienced digitizer often acts as a consultant, suggesting small modifications to the original artwork that will produce a much better final product. This partnership between the client and the digitizer is what ensures the final design is not just stitched, but expertly crafted.

In conclusion, custom digitizing is the critical link between a unique concept and a tangible, high-quality embroidered item. For any brand, team, or individual that needs a design rendered accurately in thread, investing in a skilled custom digitizer is the most important step toward achieving a lasting and professional impression.