"Executive Summary Automotive Parts Die Casting Market Size, Share, and Competitive Landscape

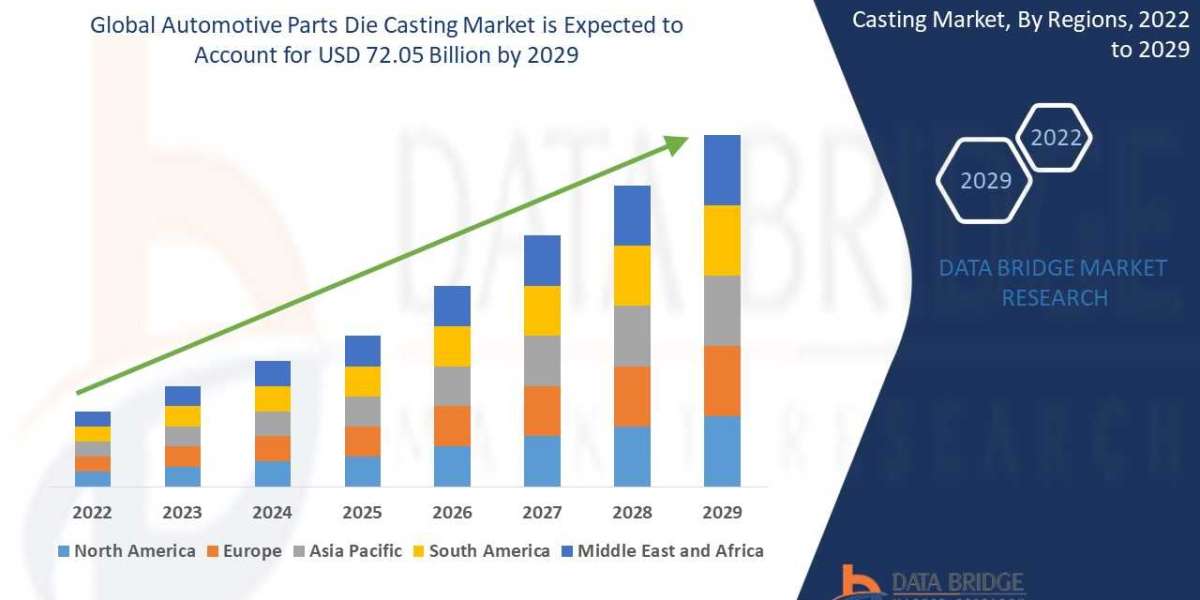

Global automotive parts die casting market size was valued at USD 52.12 billion in 2024 and is projected to reach USD 87.50 billion by 2032, with a CAGR of 6.69% during the forecast period of 2025 to 2032.

To attain knowhow of market landscape, brand awareness, latest trends, possible future issues, industry trends and customer behavior, the finest Automotive Parts Die Casting Market research report is very crucial. The report also identifies and analyses the intensifying trends along with major drivers, challenges and opportunities in the market. This market report is a source of information about Automotive Parts Die Casting Market industry which puts forth current and upcoming technical and financial details of the industry to 2029. Global Automotive Parts Die Casting Market business report has been formed with the appropriate expertises that utilize established and unswerving tools and techniques such as SWOT analysis and Porter's Five Forces analysis to conduct the research study.

The high quality Automotive Parts Die Casting Market business report encompasses a range of inhibitors as well as driving forces of the market which are analysed in both qualitative and quantitative manner so that readers and users get precise information and insights. All the data and statistics covered in this report are backed up by latest and proven tools and techniques such as SWOT analysis and Porter's Five Forces Analysis. For in depth perceptive of market and competitive landscape, the report serves a lot of parameters and detailed data. The universal Automotive Parts Die Casting Market report is prepared by performing high level market research analysis of key marketplace segments to identify opportunities, challenges, drivers, and market structures for the clients.

See what’s driving the Automotive Parts Die Casting Market forward. Get the full research report:

https://www.databridgemarketresearch.com/reports/global-automotive-parts-die-casting-market

Automotive Parts Die Casting Industry Landscape

**Segments**

- By Production Process: Pressure Die Casting, Vacuum Die Casting, Squeeze Die Casting

- By Raw Material: Aluminum, Zinc, Magnesium, Others

- By Application: Body Assemblies, Engine Parts, Transmission Parts, Others

The global automotive parts die casting market is segmented based on different criteria to provide a comprehensive analysis of the industry. In terms of production process, the market is divided into pressure die casting, vacuum die casting, and squeeze die casting. Pressure die casting is a widely used method for producing automotive parts due to its cost-effectiveness and high efficiency. Vacuum die casting offers improved surface finish and is commonly used for producing complex parts with thin walls. Squeeze die casting, on the other hand, is known for its capability to produce large parts with high strength and hardness.

When it comes to raw materials, the market is categorized into aluminum, zinc, magnesium, and others. Aluminum die casting dominates the market owing to its lightweight properties, corrosion resistance, and recyclability. Zinc die casting is preferred for its high strength and dimensional stability, especially for components that require intricate shapes. Magnesium die casting is gaining traction in the automotive industry due to its excellent strength-to-weight ratio and high thermal conductivity. The others segment includes materials such as copper, brass, and steel which are used for specific applications in automotive die casting.

Under the application segment, the market is segmented into body assemblies, engine parts, transmission parts, and others. Body assemblies include components like chassis, panels, and structural parts that require high precision and durability. Engine parts manufactured through die casting include cylinder blocks, cylinder heads, and engine mounts that demand high thermal conductivity and dimensional accuracy. Transmission parts such as gear housings and shift forks benefit from die casting's ability to produce complex shapes with tight tolerances. Other applications encompass a wide range of automotive components like steering systems, brake components, and HVAC parts that are essential for vehicle performance and safety.

**Market Players**

- Endurance Technologies Limited

- Alcast Technologies

- Dynacast

- Ryobi Limited

- Rockman Industries Ltd.

- Sandhar Technologies Limited

- Gibbs Die Casting Corporation

- Martinrea Honsel

- Pace Industries

- Ningbo Baishi Mould Co., Ltd.

The global automotive parts die casting market is highly competitive with the presence of several key players that are focusing on technological advancements, product innovation, and strategic collaborations to gain a competitive edge. Companies such as Endurance Technologies Limited, Dynacast, and Gibbs Die Casting Corporation are prominent players in the market known for their quality products and strong market presence. Collaborations and partnerships with automotive OEMs and component suppliers are helping companies like Alcast Technologies and Rockman Industries Ltd. expand their market reach and enhance their product offerings. With increasing demand for lightweight and fuel-efficient automotive components, market players are investing in research and development to develop advanced die casting solutions that meet the evolving requirements of the automotive industry.

The global automotive parts die casting market is witnessing significant growth driven by increasing demand for lightweight yet durable components in the automotive industry. As technology continues to advance, there is a growing need for innovative die casting solutions that can meet the stringent requirements of modern vehicles. Market players are focusing on developing new production processes such as vacuum die casting and squeeze die casting to cater to the diverse needs of automotive manufacturers. These methods offer improved surface finish, high strength, and the ability to produce complex parts, providing a competitive advantage in the market.

In terms of raw materials, aluminum remains the most widely used material for die casting due to its favorable properties such as lightweight, corrosion resistance, and recyclability. However, there is a rising trend towards the adoption of magnesium die casting, driven by its excellent strength-to-weight ratio and thermal conductivity. This shift towards magnesium is reflective of the industry's push towards reducing overall vehicle weight and enhancing fuel efficiency. Additionally, the utilization of zinc die casting for components requiring high strength and dimensional stability underscores the versatility of die casting in meeting various material requirements of automotive applications.

The segmentation of the automotive parts die casting market by application highlights the diverse range of components that are manufactured using die casting processes. Body assemblies, engine parts, and transmission parts each have unique demands in terms of precision, durability, and performance characteristics. The ability of die casting to produce intricate shapes with tight tolerances makes it a preferred manufacturing method for critical components such as engine mounts, transmission housings, and structural parts. As automotive OEMs continue to prioritize efficiency and performance, die casting remains a crucial technology in delivering high-quality components that meet stringent industry standards.

Key market players such as Endurance Technologies Limited, Dynacast, and Gibbs Die Casting Corporation play a significant role in driving innovation and competitiveness in the automotive parts die casting market. These companies are investing in research and development to design advanced solutions that address current industry challenges and meet the evolving needs of automotive manufacturers. Collaborations and partnerships with OEMs and suppliers are enabling market players to expand their product offerings and enhance their market presence. With the automotive industry's focus on sustainability and performance, the demand for high-quality die-cast components is expected to continue growing, presenting opportunities for market players to differentiate themselves through innovative solutions and strategic partnerships.The global automotive parts die casting market is a dynamic and competitive industry with a strong focus on technological advancements and product innovation. Key market players such as Endurance Technologies Limited, Dynacast, and Gibbs Die Casting Corporation are driving the market forward by continuously investing in research and development to meet the evolving needs of automotive manufacturers. These companies are leveraging strategic collaborations with automotive OEMs and component suppliers to expand their market reach and enhance their product offerings. By staying at the forefront of innovation, market players are able to differentiate themselves and gain a competitive edge in a rapidly changing landscape.

In terms of production processes, advancements such as vacuum die casting and squeeze die casting are providing manufacturers with new capabilities to produce high-quality automotive parts. Vacuum die casting, with its improved surface finish, and squeeze die casting, known for producing large parts with high strength, are enabling manufacturers to meet the stringent requirements of modern vehicles. These innovative production processes are essential for addressing the demand for lightweight yet durable components in the automotive industry.

Raw materials play a crucial role in the automotive parts die casting market, with aluminum remaining a popular choice due to its lightweight properties, corrosion resistance, and recyclability. However, the increasing adoption of magnesium die casting reflects a growing trend towards lightweight materials with high strength-to-weight ratios and thermal conductivity. This shift towards magnesium, along with the continued use of zinc die casting for components requiring high strength and dimensional stability, demonstrates the versatility of die casting in meeting the diverse material requirements of automotive applications.

The segmentation of the market by application underscores the diverse range of components that are manufactured using die casting processes. Body assemblies, engine parts, and transmission parts each have specific demands in terms of precision, durability, and performance characteristics. The ability of die casting to produce complex shapes with tight tolerances makes it an ideal manufacturing method for critical components across various automotive systems. As the automotive industry continues to emphasize efficiency, performance, and sustainability, the demand for high-quality die-cast components is expected to grow, presenting opportunities for market players to innovate and collaborate to meet the evolving needs of the market.

Review the company’s share in the market landscape

https://www.databridgemarketresearch.com/reports/global-automotive-parts-die-casting-market/companies

Automotive Parts Die Casting Market – Analyst-Ready Question Batches

- What regulatory frameworks govern this Automotive Parts Die Casting Market industry?

- What proportion of sales come from promotions or discounts?

- What is the average shelf life of the Automotive Parts Die Casting Market product?

- How important is personalization in this Automotive Parts Die Casting Market?

- What are the trends in user-generated content for Automotive Parts Die Casting Market?

- What is the average profit margin per unit?

- What’s the demand trend across income groups?

- What portion of sales comes from Tier II III cities?

- Which retailers dominate product placement?

- What’s the average customer acquisition cost for Automotive Parts Die Casting Market?

- What new market segments are emerging?

- What are the effects of digital transformation?

- Which trends are influenced by Gen Z consumers?

- What are the implications of the circular economy for Automotive Parts Die Casting Market?

Browse More Reports:

Global Energy Recovery Ventilator Market

Global Engineered Wood Packaging Market

Global Enterprise Very Small Aperture Terminal (VSAT) Market

Global E-Prescription Market

Global Essential Oils in Animal Nutrition Market

Global Ethylene Vinyl Acetate Copolymer Market

Global Expanded Thermoplastic Polyurethane Market

Global Extended Reach Drilling Technology Market

Global Extruded Nets Market

Global Fabric Care Market

Global Face Oil Market

Global Facioscapulohumeral Muscular Dystrophy Market

Global Farm Management Software and Services Market

Global Farm Tire Market

Global Feed Anticoccidials Market

Middle East and Africa Thyroid Cancer Diagnostics Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com

"