In today’s world of manufacturing, businesses are always under pressure to make as much as possible, keep costs down, and keep the quality of their products the same. In the past, manual processes were well enough to handle supply chains and customers’ needs. But now, they aren’t enough. This is where production operations management software really shines.

These software programs let firms improve productivity, cut down on downtime, and boost long-term growth by bringing planning, monitoring, and optimisation together in one place. Let’s look at how a robust production management system may change the way things are made and why it is becoming the most important part of Production and Operations Management.

What is software for managing production operations?

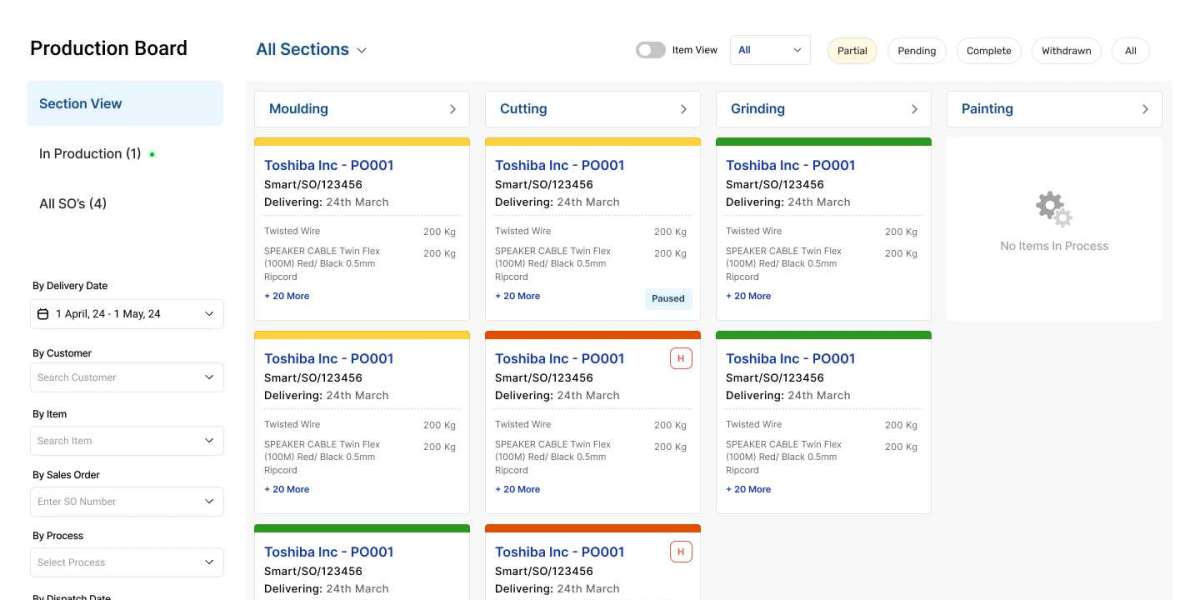

Production Operations Management Software is a computer program that helps you manage, regulate, and get the most out of all parts of production operations. It bridges the gap between operational execution and strategic planning by giving manufacturers power, visibility, and data-driven insights.

This software is different from basic ERP modules that focus on finance or inventory because it is specialized in:

Making production scheduling easier.

Allowing for real-time monitoring of shop floor activities.

Improving quality control and following the rules.

Making reports and analytics automatic.

It’s the backbone of a modern way to manage manufacturing, making sure that everything runs smoothly from procuring raw materials to delivering final goods.

Importance in Production and Operations Management

The goal of Production and Operations Management is to get the most work done by using resources like people, machines, and materials. Without the right tools, businesses can run into problems including delays, a lack of transparency, and inconsistent production.

Production software makes operations management better by:

Standardising processes makes sure that workflows are the same across all plants and teams.

Real-time Visibility: Managers may keep an eye on performance KPIs like OEE (Overall Equipment Effectiveness).

Regulatory Compliance: Integrated quality checks and audit trails lower the risks of not following the rules.

Decisions based on data: Analytics help with capacity planning and lowering costs by giving you useful information.

So, setting up a production management system isn’t only about going digital; it’s also about making sure that operations are in line with business goals.

Important Features of Production Operations Management Software

Let’s look at some of the most important elements that make this software so useful:

- Planning and scheduling production Producers can use advanced scheduling algorithms to make sure they get their deliveries on time, use their resources wisely, and cut down on idle time.

- Managing resources and inventory The software keeps track of inventory levels on its own, making sure that there are always enough raw materials and spare parts on hand. This keeps stock levels low and prevents stockouts.

- Making sure the quality Integrated quality management systems help find problems early and make sure that every unit meets industry requirements.

- Watching in real time Dashboards that use the Internet of Things (IoT) offer real-time updates on how well machines are working, how productive workers are, and how much output they are producing.

- Reporting and analytics managers can see trends in production, what causes costs, and where things might be better by putting data into meaningful reports.

- Warnings and Alerts Repeating tasks and schedules optimized result in increased throughput without increased labor costs.

Cost Efficiency

Proper planning and making the most use of resources cut down on waste and operational costs.

Higher Quality of Products

Real-time monitoring makes ensuring that quality requirements are fulfilled, which cuts down on rework and customer complaints.

Better Collaboration: Cloud-based tools let diverse teams, such manufacturing, procurement, and sales, work together.

Scalability

The system can be changed to keep up with changes in production levels, new product lines, or growth into new markets.

Clear Data

Management can make quick decisions with centralised dashboards that provide them a full view of activities.

Part in the digital transformation of manufacturing

Digital transformation is now a must as firms move to Industry 4.0. Production Operations Management Software is a driver by:

Working with supply chain, ERP, and CRM applications.

Using AI and machine learning to do predictive maintenance.

Making it possible for IoT-enabled devices to collect data in real time.

Helping to make things more sustainable by optimizing energy and materials.

In short, the production management system is the most important part of smart factories, where automation, analytics, and flexibility all come together.

How to Choose the Right Software for Managing Production Operations

Your operations strategy might be helped or hurt by the correct platform. Remember these things:

Easy-to-use Interface: A basic system that doesn’t need any training makes it easy to use.

Scalability: The software should be able to grow with your business.

Compliance and Security: It’s important to protect data and follow industry standards.

Scalability: The software should be able to scale up with your business.

Security and Compliance: Data protection and adherence to industry standards are essential.

Vendor assistance: Reliable customer service and technical assistance post-sales ensures easier sailing.

What will the future hold for production and operations management

Emerging technologies are impacting the future of Production and operations management. Manufacturers are anticipating:

Predictive analytics driven by artificial intelligence that will anticipate demand and ensure things keep humming along.

Digital twins to simulate production lines and experiment with them in a virtual environment to determine if they can be optimized.

Infusing blockchain in supply chains to open them up.

Augmented Reality (AR) for instruction staff and equipment upkeep.

Those companies that adopt these new technologies in addition to a strong production control system will stay ahead of the game.

Conclusion

For those manufacturers that want to excel in a globalized and competitive environment, production operations management software is no longer an option but a requirement. It transforms the way factories work by giving them real-time visibility, higher production, and maintaining quality.

Regardless of size, investing in a strong production management system can release savings, lower costs, and future-proof operations.

As Production and Operations Management expands, organizations utilizing advanced digital technologies will be the first to make the transition to smarter, faster, and greener manufacturing.

Original reference: https://blogwebsite79.wordpress.com/2025/09/12/production-operations-management-software-making-modern-manufacturing/