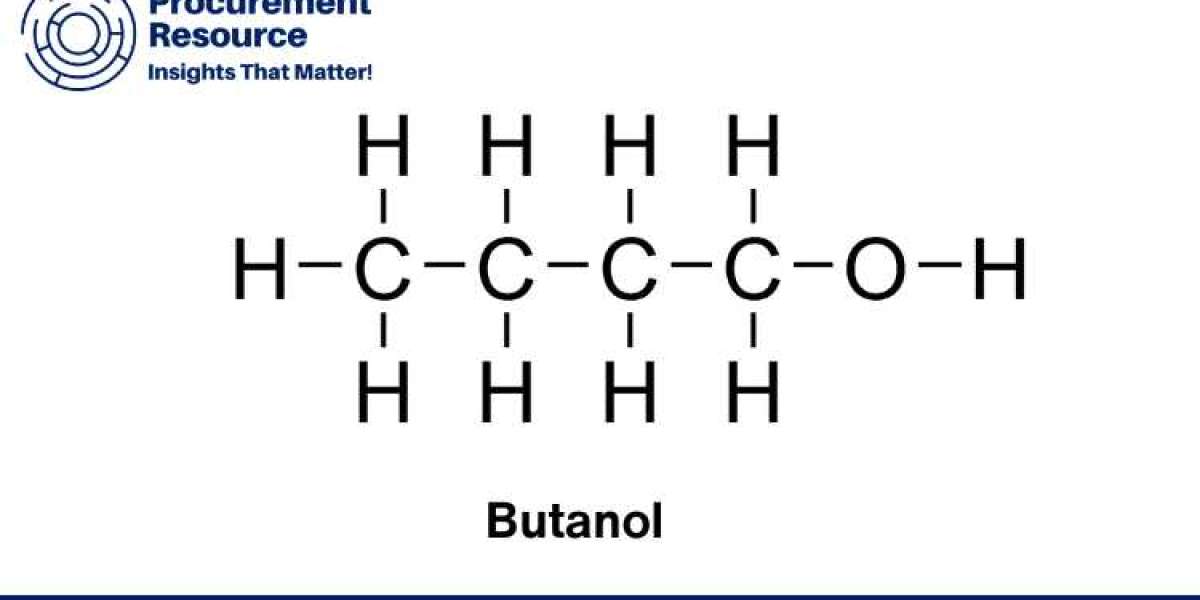

Butanol, a four-carbon alcohol, is widely used as an industrial solvent, in the production of plastics, as an additive in fuels, and in the manufacturing of various chemicals such as butyl acetate and plasticizers. The production of butanol is a significant process in the chemical industry, and understanding the butanol production cost is essential for manufacturers and stakeholders to remain competitive in the market. This article provides an in-depth look into the Butanol Production Cost, breaking down various factors that influence costs, such as cost model, pre-feasibility analysis, industrial trends, labor charges, utilities, logistics, and supply chain factors.

Request For Sample: https://www.procurementresource.com/production-cost-report-store/butanol/request-sample

Extensive Butanol Production Cost Report: Cost Model

The Butanol production cost is primarily influenced by several critical components, such as raw material costs, labor expenses, energy consumption, and the technological processes involved. The production of butanol typically follows two major routes: the traditional oxo process (also called the hydroformylation process) and biobutanol production.

Oxo Process (Hydroformylation Process): This involves the reaction of propylene with synthesis gas (carbon monoxide and hydrogen) in the presence of a catalyst, resulting in the formation of butyraldehyde, which is subsequently hydrogenated to form butanol. This process is energy-intensive and requires significant investments in catalysts and reactors, making it an expensive option for production.

Biobutanol Production: Biobutanol is produced through the fermentation of sugars using microorganisms such as Clostridium acetobutylicum. Although this process has the potential to reduce production costs, it still faces challenges in terms of scale, efficiency, and the cost of feedstock.

The cost model for butanol production takes into account raw materials, energy requirements, labor, and overheads. By optimizing the production process and choosing cost-efficient methods, manufacturers can reduce their production costs and improve their competitive edge in the market.

Pre-feasibility Analysis of Butanol Production

Before embarking on any large-scale production of butanol, a pre-feasibility analysis is essential. This analysis considers several factors that could influence the economic viability of the project, including:

Raw Material Availability and Cost: The cost and availability of raw materials (propylene for oxo process, sugars for biobutanol) play a crucial role in determining the production cost. The pre-feasibility study helps identify cost-effective sources and assess the impact of fluctuating raw material prices on the overall project.

Technology Selection: A decision must be made between the oxo process and biobutanol production. Although the biobutanol process has lower environmental impact, it is still less commercially viable due to high production costs. Hence, a detailed cost-benefit analysis helps choose the most efficient and cost-effective technology for production.

Regulatory and Environmental Compliance: Manufacturers must ensure that their operations comply with environmental regulations. This may involve investment in pollution control systems, safety measures, and waste management, all of which affect the capital and operational costs of the project.

Market Analysis: Analyzing market trends, demand for butanol, and competitor activities are critical components of the pre-feasibility analysis. The pre-feasibility report will help stakeholders determine if the projected revenues justify the investment.

Industrial Trends in Butanol Production

Industrial trends significantly influence the Butanol production cost over time. The global shift towards sustainable practices and the increasing demand for bio-based chemicals are important trends in the industry. Below are some of the key industrial trends that shape butanol production:

Shift Towards Green Chemistry: There is growing interest in biobutanol due to its environmental benefits. Biobutanol is renewable and reduces dependence on fossil fuels, making it an attractive alternative to traditional butanol production methods. Although biobutanol production still faces challenges such as high feedstock costs and fermentation inefficiencies, advancements in biotechnology and fermentation processes may help reduce its production costs in the future.

Cost Reduction Technologies: Advances in process optimization and automation have made butanol production more cost-efficient. The development of more efficient catalysts and improvements in the oxo process have helped reduce energy consumption, which directly impacts production costs. Furthermore, the integration of green technologies into butanol production can potentially reduce costs while also meeting environmental standards.

Demand for Biofuels: With increasing demand for biofuels, there is a rising interest in butanol as a potential fuel additive. Bio-based butanol has the potential to replace traditional fuel additives like MTBE, offering environmental and cost benefits. As a result, increased demand for butanol in the fuel sector is expected to have a significant influence on its production economics.

Labor Charges in Butanol Production

Labor charges account for a substantial part of the overall Butanol production cost. Skilled labor is required to operate and maintain the production equipment, ensure safety compliance, and manage the production processes. Labor costs vary by region due to differences in wage structures, labor availability, and the skill set required for different stages of production.

In countries with lower labor costs, the overall cost of production may be reduced, making it more economically feasible to establish a butanol production facility. However, labor costs can also rise with the need for specialized workers and the implementation of automated processes. Automation has been increasingly integrated into butanol production facilities to reduce labor dependence and lower operational costs.

Utilities and Energy Consumption

Butanol production is an energy-intensive process, especially in the oxo process, where high temperatures and pressures are required for the reaction. Therefore, energy consumption constitutes a significant part of the Butanol production cost. Factors such as the availability of cheap and reliable energy sources play an important role in determining the overall cost of production.

Utilities like water, steam, and electricity are essential to maintain operations. In many regions, fluctuating energy prices can have a direct impact on production costs, making energy efficiency a key area for cost optimization. Some companies are looking into alternative energy sources, such as solar and wind power, to lower energy costs and reduce their carbon footprint.

Logistics and Supply Chain

The logistics and supply chain play a crucial role in butanol production, particularly in ensuring the timely and cost-effective delivery of raw materials and the distribution of finished products. Raw materials, such as propylene or sugar, are typically sourced from different regions, which means transportation costs can significantly affect the overall production cost.

Effective supply chain management is essential to reduce bottlenecks and delays in production, ensuring a smooth flow of materials from suppliers to manufacturers. Additionally, companies must carefully manage their storage capacities and distribution channels to reduce costs and minimize risks associated with inventory and transportation.

Request a Free Sample

If you are considering entering the butanol production industry or wish to assess the feasibility of your current butanol production process, a detailed cost report is essential for making informed decisions. To get a comprehensive and customized Butanol Production Cost report, click the link below to request a free sample from Procurement Resource.

Request a Free Sample: https://www.procurementresource.com/production-cost-report-store/butanol/request-sample

Understanding the Butanol Production Cost is crucial for manufacturers, investors, and stakeholders looking to optimize production processes, reduce costs, and improve profitability. From the selection of production methods and raw materials to labor charges, energy consumption, and logistics, each factor plays a role in determining the overall cost of production. By staying informed about industrial trends, technological advancements, and market demands, companies can navigate the challenges of butanol production and capitalize on emerging opportunities in the biofuels and chemicals markets.

Contact Us:

Company Name: Procurement Resource

Contact Person: Endru Smith

Email: sales@procurementresource.com

Toll-Free Number: USA Canada - Phone no: +1 307 363 1045 | UK - Phone no: +44 7537171117 | Asia-Pacific (APAC) - Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA